Windshield Wiper Motor

BEHAVIOR

It provides the muscle to move the wipers back and forth across the

windshield.

HABITAT

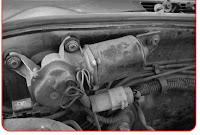

The wiper motor is mounted on the top of the firewall at the back of

the engine compartment.

HOW IT WORKS

This is a high-torque electric motor supplied with power from the battery.

When you turn on the wipers, the motor converts electric energy into rotary mechanical energy. The output of the motor turns a worm gear, which looks like a spiral of metal wrapped around a metal rod.

Worm gears are fundamentally different from other gears in several ways. They can radically increase the turning power or torque, which is useful in applications such as windshield wipers. And they change the

direction of rotation. In the windshield wiper the worm gear changes the direction of the motor shaft’s rotation 90 degrees.

The worm gear meshes with another gear. This arrangement decreases the speed of the motor’s rotation and increases again the torque. This second gear shares its axle with a cam or crank. These devices change the motion from rotary motion produced by the motor to the back-and-forth motion of the wipers. The cam or crank connects to a rod that drives the driver’s wiper and to another rod that drives the passenger’s side wiper.

The wiper motor is a direct current motor; its speed is governed by the voltage it receives. So to change the speed of the wipers, different voltages (up to 13 volts maximum) are fed to the motors.

Wiper motors have a park feature. When you turn the wipers off, they continue wiping, but stop in their normal rest or park position. To get the wipers to return to their park position when you shut them off,

the motor has two additional electrical contacts. A circuit feeds power to them after you have cut power by switching off the wipers.

INTERESTING FACTS

Before electric motors were used to drive windshield wipers, the engine’s vacuum pressure supplied the power. This meant that the wipers went faster when the engine went faster. Going up a steep hill reduced the speed of the windshield wipers. Electric motors replaced the vacuum pressure wipers starting in 1926.

A field guide to automotive technology

Ed Sobey

Cover and interior design: Joan Sommers

Photo on page 28: © Smokey Combs

© 2009 by Ed Sobey

All rights reserved

Published by Chicago Review Press, Incorporated

814 North Franklin Street

Chicago, Illinois 60610

ISBN: 978-1-55652-812-5

Printed in the United States of America

for more details and updates about automotive-technology-guide please visit.........

www.automotive-technology-guide.com

---or---